When You Should Use A Compression Spring MachineUpdate:2025-03-13 Hot:149

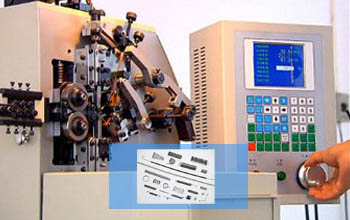

Xinding range of compression spring machines can accommodate every requirement, from tiny compression springs with wire diameters measuring as little as 0.07 mm right through to the other end of the scale at up to 8 mm.A compression spring machine is used when you need to manufacture compression springs efficiently and with precision. Following are some scenarios when you should use a compression spring machine.

1. High-Volume Production

If you need to produce a large number of compression springs consistently, a compression spring machine is ideal. It automates the process, ensuring uniformity and reducing production time.

2. Precision and Consistency

When your application requires springs with precise dimensions, load characteristics, and tolerances, a compression spring machine ensures consistent quality across all units.

3. Custom Spring Designs

If you need custom-designed compression springs with specific wire diameters, coil counts, or end configurations, a spring coiling machine can be programmed to meet these requirements.

4. Material Efficiency

Compression spring machines are designed to minimize material waste by accurately coiling wire to the required specifications, making them cost-effective for material-intensive projects.

5. Complex Spring Geometries

For springs with complex shapes, such as variable pitch, tapered coils, or special end configurations, a compression spring machine can handle these designs with ease.

6. Reduced Labor Costs

Automating the spring manufacturing process reduces the need for manual labor, lowering production costs and minimizing human error.

7. Quick Prototyping

If you need to prototype or test different spring designs, a compression spring machine allows for rapid adjustments and production of small batches.

8. Industries with Specific Requirements

Industries like automotive, aerospace, medical devices, and electronics often require high-quality compression springs. A compression spring machine ensures compliance with industry standards.

9. Cost-Effective for Medium to Large Batches

While setting up a compression spring machine may require an initial investment, it becomes cost-effective for medium to large production runs.

10. Maintaining Quality Standards

If your business requires adherence to strict quality control standards, a compression spring machine ensures that each spring meets the required specifications.

When Not to Use a Compression Spring Machine:

For very small batches or one-off prototypes, manual spring winding or outsourcing might be more cost-effective.

If you lack the technical expertise to operate or maintain the machine, outsourcing may be a better option.

In summary, a compression spring machine is best used when you need high-volume, precise, and consistent production of compression springs, especially for custom or complex designs.

Related News

- What is Spring Grinding Machine2024-03-15

- How to choose CNC spring machine2021-12-16

- Power Failure Of Computer Spring Machine And Its Solution2021-09-28

- Medical Equipment Precision Spring2021-07-05

- Spring Machine Daily Maintenance2021-03-05